CXK32 main technical data

| Controls | Siemens801 |

| Max.workpiecelength | 32mm |

| Max.workpiecelength | 120mm |

| Feed rate:X/Z axis | 150/80mm |

|

Fast feed X/Z axis |

15m/min |

| Max.cutter head speed | 3000rpm |

| Max.milling head speed | 2000rpm |

| positioning accuracy | X/Z 0.015mm |

| Repeatedpositioning accuracy | X/Z 0.01mm |

| Dimensions | 1400*1050*1430m |

| Weight | 500Kg |

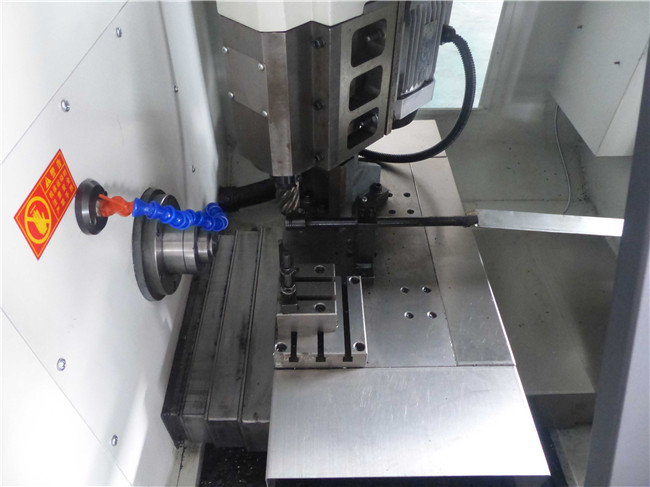

[Turning & milling complex bit machine]

main features

一、The Turning & milling complex bit machine can finsh turning,milling etc much more process by once clamping on the one end of the bit.二、Patent machine use the principle of motion degree,which complete the workpiece during synchronizing the cutting tool with the workpiece.workpiece will be finshed turning,millingand rubdown basis on once clamping with high efficiency and precision.then to avoid the accumulated error of the traditional process's multiple clamping.

Main features:

1、The structure optimization of high strength, high rigidity Meehanite cast iron body fully absorb the cutting vibration, ensure the stability of the machining accuracy of machine tool. Each axis of motion with high precision linear guide and ball screw, imported precision bearing group. The machine can be equipped with automatic feeder, automatic feeder, automatic chip removal, automatic door and all kinds of additional facilities, and flexible production lines, to achieve automatic processing

2、The CNC machine can finish turning,milling etc much more process by once clamping on the one end of the bit.

3、Workpiece will be finish turning ,milling and rubdown basis on once clamping with high efficiency and precision.Then to avoid the accumulated error of the traditional process's multiple clamping.

4、 feeding and blanking automaticlly,one worker can operate multiple machines.with high work efficiency and low labor strenghth.

5、6-8pcs/min(PH2pillips),

In order to ensure the quality of products, not recommended speed

【Service and Technical support】

(1) to analysis of the drawings and samples for your company, free production process design, workshop equipment and personnel necessary.

(3) can provide optimum processing scheme, processing all types of products for your company such as: material processing what, what brand value.

(5)、 the price of the machine tool for processing standard price, customer demand for different, the final price is determined according to the actual situation.

【Pre-sale + after sale service】

Before sale: to analysis of the drawings, process efficiency, according to

customer requirements to provide proof. To provide complete solutions for

customers

Sales: binding machine, to provide free technical training, customer Commissioner learning operation, the equipment installation and debugging, you can smooth the normal operation of the production